Design & Installation

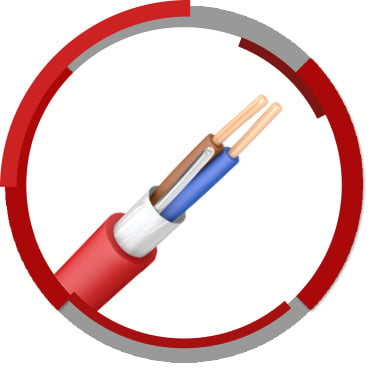

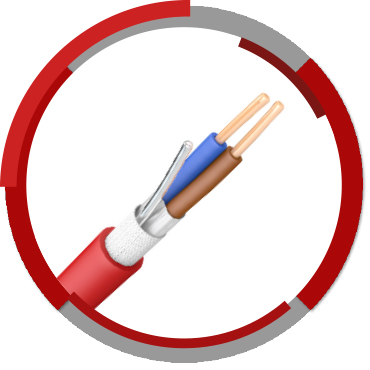

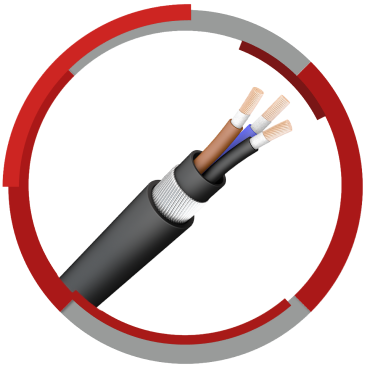

Circuit integrity is the critical task required by fire resistant cables which means the cable must keep working by maintaining voltage and current safely to keep the system working. The resistance to fire of the cable fixings, cable support system and any joints should be at least equivalent to the survival time of FP500 cable. The cable should either be fixed directly to the building structure or be installed such that they are enclosed in or carried upon cable management or support systems.

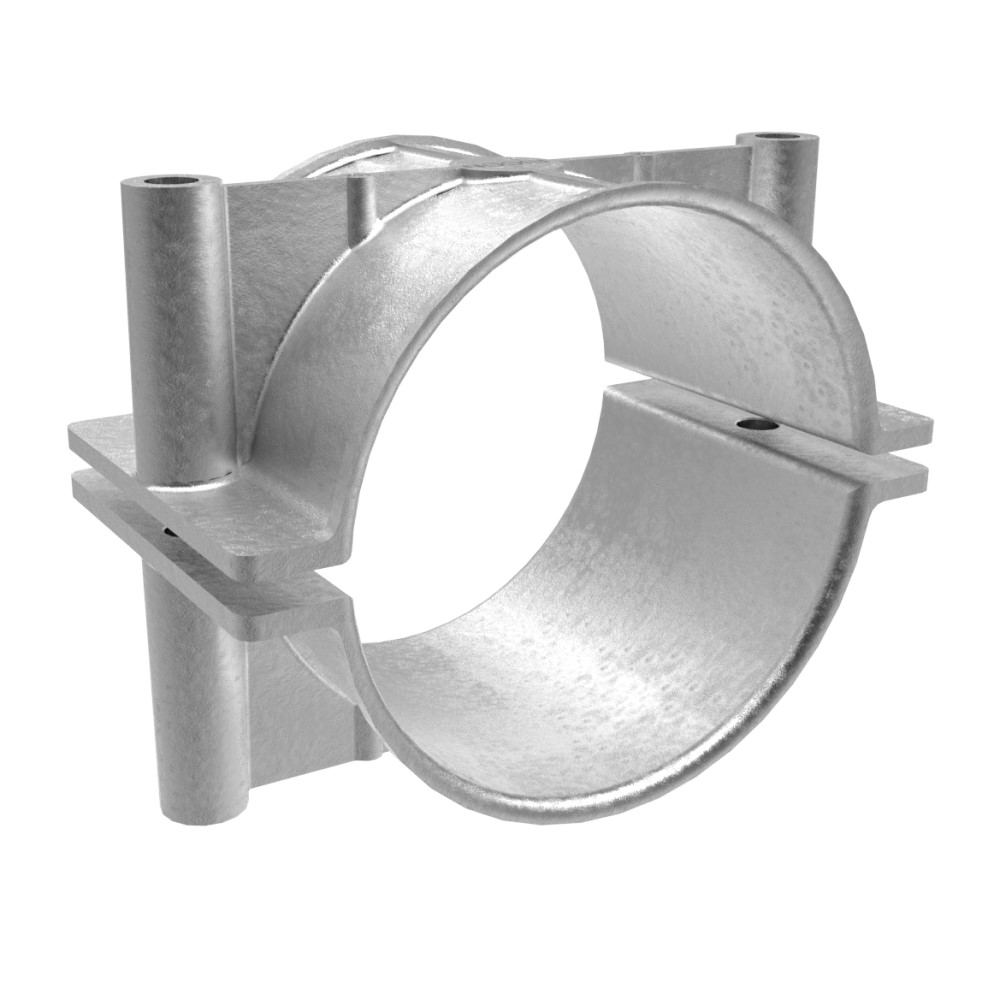

Copper or ferrous fixings are suitable but aluminium with a melting point 660˚C, is not. As well as being non burning – any fixing selected should not impede the cable performance during a fire – to guarantee that the cable will carry on working. Choose BICON cable accessories by Prysmian which have been fire tested with their associated Prysmian FP cables.