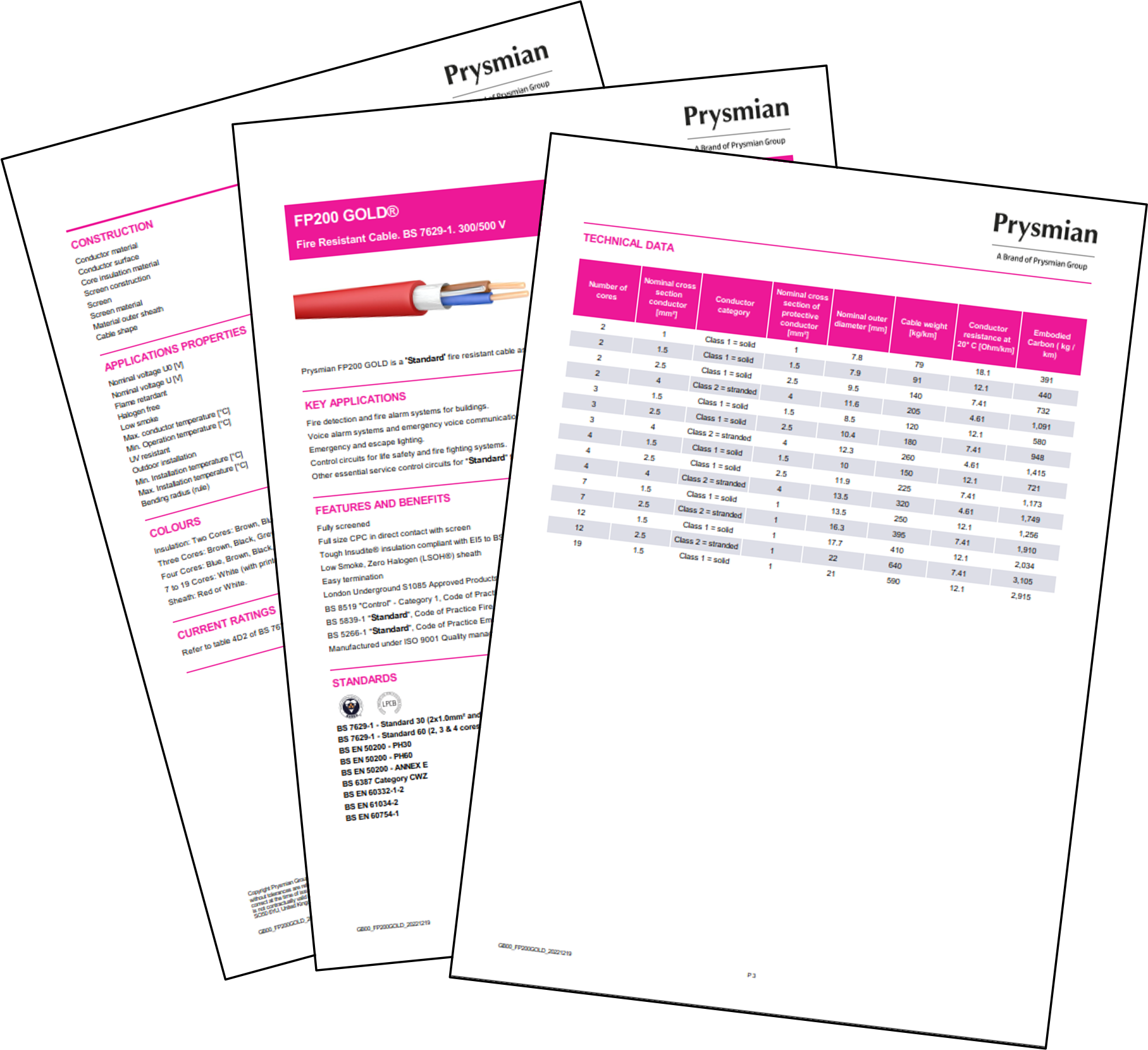

What is Embodied Carbon?

Embodied carbon quantifies the greenhouse gas emissions associated with the construction, use and demolition of a building or infrastructure project, including all materials such as cables. It contributes to the carbon footprint of the entire structure and accounts for emissions throughout its lifecycle, including demolition and recycling.

Embodied carbon is assessed as “embodied carbon dioxide equivalent” (eCO₂e) or “global warming potential”, measured in kilograms of carbon dioxide (kg CO₂e).