Prysmian fire safety for major hotel upgrade

Expert technical support combined with high quality fire performance cable is the contribution of Prysmian to a major city-centre hotel upgrade.

Over 6000 metres of Prysmian Fire Performance (FP) cable are being installed by contractor RJM as part of a project to enhance the hotel's life safety building service systems. The project works include installation of a new standby generator along with almost 3km of Prysmian FP500 armoured fire-resistant control cable and over 3km of Prysmian FP600 fire resistant armoured power cable.

The highly qualified Business Development managers at Prysmian provided technical support to the consultant with a detailed review of the cable specification, ensuring, in particular, compliance with BS8519:2020 Selection and installation of fire-resistant power and control cable systems for life safety, fire-fighting and other critical applications. Code of practice.

Clause 11 of this Code requires a very specific mechanically protected Cat 3 cable to be used with the life safety-critical automatic transfer switch (ATS) that communicates with life safety back-up diesel generators. In this case, FP500 cable provided the fully compliant solution with armour protection built into the design of the cable.

Renovation and enhanced safety combined

The hotel, originally opened in the mid-20th century has recently undergone a complete renovation. The new life safety diesel generator is being installed as part of the hotel’s ongoing upgrade programme. It is connected to the hotel's life safety systems by Prysmian Fire Performance armoured control and power cables.

Under the scheme, the new generator has been installed in the Level 4 plantroom.

A new low voltage (LV) panel is being installed to supply power from the generator to the hotel's life safety systems through new power and control cabling in accordance with BS 8519:2020.

BS 8519:2020 in practice

The new updated British Standard provides guidance and recommendations on the selection and installation of fire-resistant power and control cable systems to ensure circuit integrity of life safety and firefighting systems is maintained in the event of a fire or cable fault.

Importantly, the code of practice mandates that the power supply to each life safety building services system incorporates an Automatic Transfer Switch (ATS) to flip from mains power to backup generator power automatically should the primary power source fail.

Equally importantly, the standard requires the ATS to be connected to the LV panel by mechanically protected Category 3 control cables in areas where mechanical damage is likely.

Prysmian FP500 Category 3 control cable

Prysmian FP500 is a Category 3 control cable incorporating galvanised steel wire armour for robust mechanical protection, eliminating the need for additional mechanical protection when using unarmoured Category 3 cable.

In this project, Prysmian FP500 has been installed from each ATS back to the LV panel to carry the signal to start the generator. Once running, Prysmian FP600s armoured power cable supplies the generated power, via the ATS, to the life safety systems to ensure continued operation.

Teamwork on design

Prysmian provided technical support to RJM, including evidence-based advice on cable performance to ensure compliance.

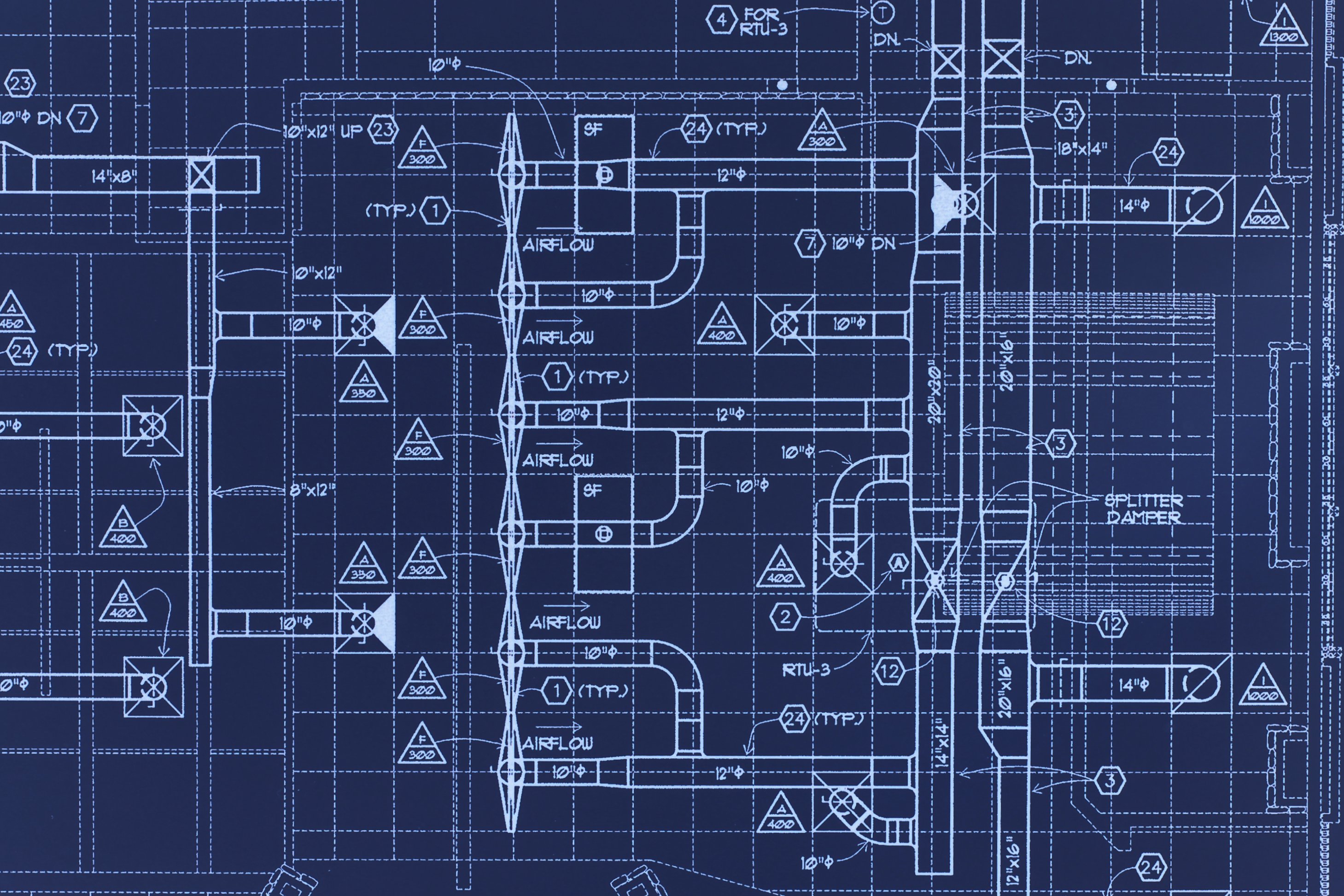

On site, RJM has installed Prysmian power and control cabling by creating new diverse routes for the cabling without compromising the existing services to enable the hotel to remain open throughout the works. "This was one of the biggest challenges of the project as the back of house is jam packed with cables, pipes, drainage and ventilation ductwork, all the while ensuring that fire compartmentation was maintained," says James Pike, RJM's Project Manager.

In total, RJM pulled over 3120m of Prysmian FP600s fire resistant, armoured power supply cabling and 2930m of Prysmian Category 3 FP500 armoured fire-resistant control cabling from the Level 4 plantroom all the way up to the lift motors on Level 29, down to the sump pumps in Basement Level 4, and to every floor in between where life safety equipment is located.

The contractor is currently installing the ATS units adjacent to the various items of life safety equipment before installing the LV panel and connecting the control and power cabling.

The project is expected to be completed by spring 2026, when the upgraded system, fully compliant to the new standards, will come into operation.