The evolution of earth conductors

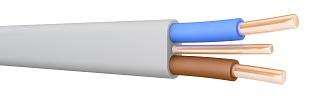

Whether you are wiring a new build or carrying out a rewire, one crucial component of your cable installation is the earth conductor – also known as the circuit protective conductor or CPC.

The CPC helps circuit designers to ensure electrical systems are safely earthed, directing fault current away from users through a low-resistance path. This quickly enables protective devices such as Residual Current Devices (RCDs) and Arc Fault Detection Devices (AFDDs) to trip, disconnecting the circuit and preventing the metal parts from remaining live. The CPC ensures that any fault current is safely directed away from users, preventing electrical shock and potential fires.

According to recent statistics from the Home Office, faulty electrics cause around 4,000 house fires every year, so it is essential that electrical installations are properly earthed to prompt the disconnection of faulty circuits and reduce the risk of fire hazards.

British Standards for earth conductors

The CPC has specific requirements under BS 6004, the British Standard that specifies the construction, performance and test methods for cable manufacturers. It is governed by BS 7671 (the IET Wiring Regulations). BS 6004:2012+A1:2020 – Electric Cables, is the specification for PVC insulated and PVC sheathed cables for voltages up to and including 300/500 V, for electric power and lighting circuits, and provides guidance on the size of the CPC built into the cable. For example, for two or three-core twin & earth cables, the nominal size would typically be as follows:

1.5mm² conductor = 1.0mm² CPC

2.5mm² conductor = 1.5mm² CPC

4mm² conductor = 1.5mm² CPC

6mm² conductor = 2.5mm² CPC

10mm² conductor = 4mm² CPC

16mm² conductor = 6mm² CPC

It is worth noting that these are nominal CPC sizes – actual CPC size may need to be determined based on the specific application and relevant regulations such as BS 7671.

The CPC is typically smaller than the live and neutral conductors because it is only designed to carry a fault current briefly during fault conditions, i.e., a short circuit. As outlined in BS 7671 clause 543.1.3, the CPC must be able to withstand the thermal energy of the fault only for the duration it takes for the protective device to disconnect the circuit. This is typically only between a fraction of a second to a few seconds. It is worth noting that a bare copper or XLPE-insulated CPC can withstand temperatures up to 250°C during fault conditions. PVC-insulated CPCs can withstand temperatures up to 160 °C.

Do you need to insulate the CPC?

In domestic and commercial applications, especially where twin and earth (T&E) cables are used, the CPC is a bare copper wire without insulation. This is because the CPC is not intended to carry current during normal, working operation. This is standard and is fully compliant with BS 7671. The bare CPC must be sleeved with green and yellow insulation at termination points to identify it as the earth conductor.

It may be necessary to insulate the CPC rather than merely sleeving it, typically in specific environments where the conductor is exposed to potential damage, corrosive environments, or when buried underground.

When did it start becoming necessary to have an earth conductor?

During the late 19th and early 20th centuries, electricity was mainly used for simple lighting circuits and had low fault currents, which is why earth conductors were not included in early cable design.

During the 1930s and 1940s, the rise of electric heating, cooking, and portable appliances meant that there was a clear need for an earth conductor. The British Standard BS 546 was introduced in 1934, which specified the use of a round pin plug that featured two poles and one earth pin. The Standard enhanced safety for users by ensuring that electrical appliances had a dedicated path to the ground. The modern 13-amp fused plug with earth pin—as we know it today—was introduced in 1947 and became mandatory in most homes.

After WWII, the building boom led to the widespread use of electricity. Following the publication of the 14th edition of the Wiring Regulations in 1966, it became mandatory to earth cables in lighting circuits.

Are there aluminium CPCs?

Earth conductors are typically made from copper. BS 7671 and BS 7430:2011+A1:2015, Code of practice for protective earthing of electrical installations, allow aluminium only under very limited conditions.

An aluminium conductor may be used for earth in overhead power lines or above-ground earthing; however, aluminium should not come into contact with soil or concrete due to the risk of corrosion. Section 9.7 of BS 7430, states aluminium or copper-clad aluminium conductors should not be used in contact with soil and should not, under any circumstances, be used to make the final connection to an earth electrode.

Prysmian LSX

Using cables such as Prysmian LSX cable provides even greater safety for electrical installations. Prysmian LSX is commonly used for lighting and small power applications in commercial installations such as offices, shops, hospitals and light industry. The cable has a bare tinned copper CPC, which allows it to conduct a fault to the protection devices. Prysmian LSX is ideal for installation in shallow voids because its in-built aluminium electrical safety screen, coupled with Type B circuit breakers, provides instant response if penetrated with a conductive metal object.

With the addition of an XLPE insulation and a LSOH sheath, Prysmian LSX provides further safety benefits in the event of nail penetration or fire. The cable also provides installers with installation benefits such as fast terminations, nylon glands and reduced containment weight.

The earth conductor remains an essential component for electrical safety. Whether you are installing standard twin & earth or specifying enhanced cables such as Prysmian LSX, understanding the role of the CPC and applying best practice can make all the difference.

If you have any questions about earthing, contact us today.