Can fibre optic cable be repaired?

Fibre optic cables can be repaired, providing you have the right tools and the right training. Fibre is often made of extremely thin strands of glass so if it is damaged in a particular area, then that section needs to be removed, and the remaining fibre would need to be carefully re-spliced together.

How do you repair fibre optic cable?

Repairing fibre optic cable can be broken down into four steps: identifying where the damage is, isolating the damaged area, repairing the damage and testing the cable.

Step one: Identify where the damage is

The obvious first step is to locate and assess the extent of the damage to the fibre optic cable. Look for any physical damage on the cable such as, exposed fibres or cuts. If the damage is not obvious, a Visual Fault Locator (VFL) can be used to identify any cracks, bends or breaks by emitting a red laser light through the fibre optic cable. Another device, the Optical Time-Domain Reflectometer (OTDR), emits pulses of light through the fibre optic cable to measure the reflections. An OTDR identifies the location and the exact extent of the damage.

Step two: Isolate the damaged area

Once the damage has been identified, the affected area of the cable should be isolated from the rest of the network. Working on fibre while light is being transmitted live through it can disrupt the light signal, causing kinks or bends that could lead to signal loss. A fibre optic splitter can be used to divide the light signal, diverting the signal away from the damaged section. It can divide the light signal into two or more outputs. Another method is to use a fibre optic switch. This device can connect or disconnect various fibre optic paths to reroute the signal.

Step three: Repair the fibre optic cable

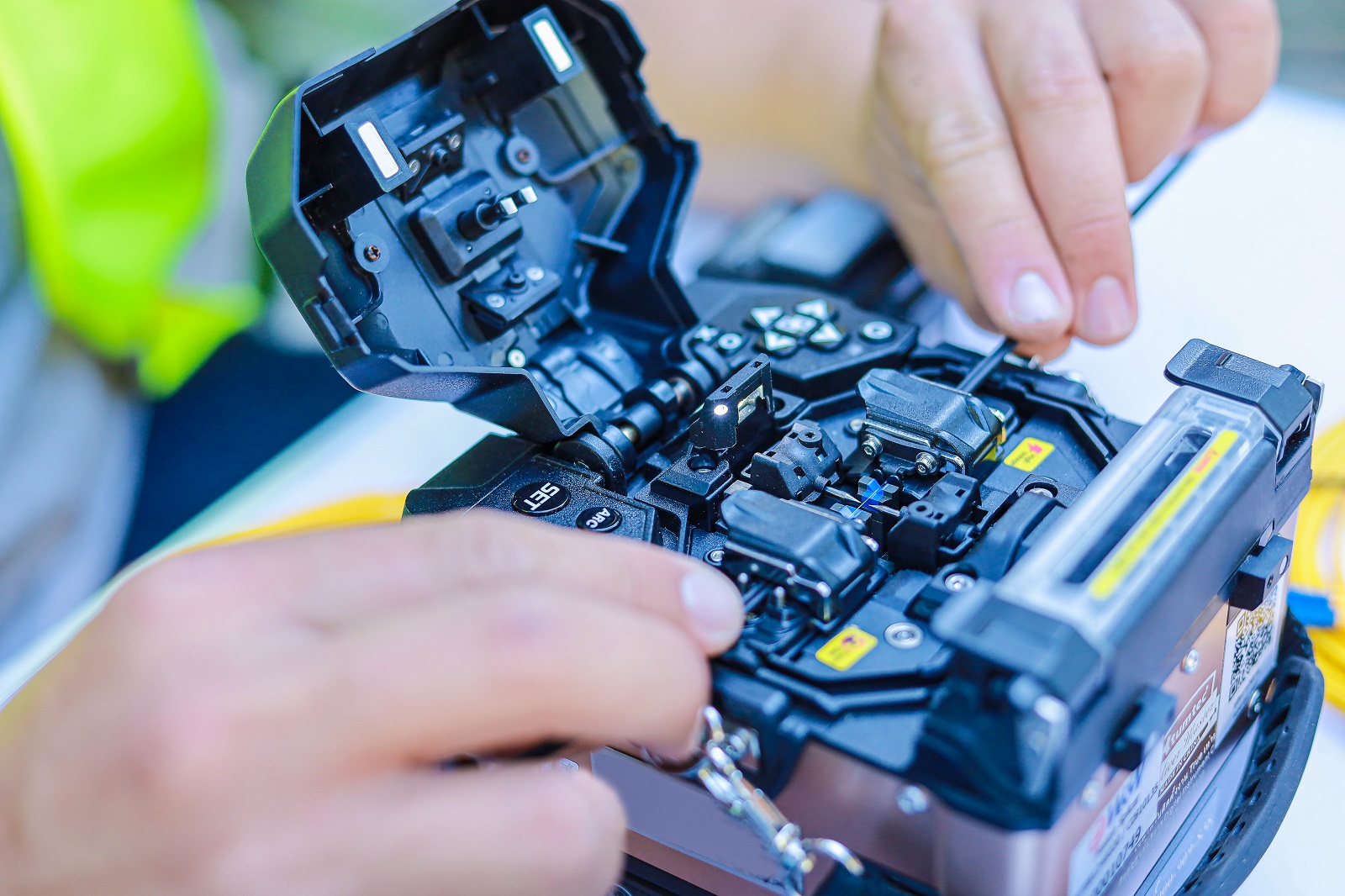

Now, the cable can be repaired. The most common methods of splicing glass optical fibre cables are fusion splicing and mechanical splicing. Fusion is typically performed using specialised fusion splicing machines. These machines heat the fibre ends with electrodes and fuse them together. Whilst this process ensures low signal loss and high mechanical strength, the machine itself can be costly.

Mechanical splicing on the other hand, involves aligning and joining fibre ends using mechanical components such as connectors or sleeves. This can be a more cost-effective method ideal for emergency repairs or temporary connections. However, mechanical spicing is old technology and is not used in the UK.

Step four: Test to ensure performance

Following repairs, the fibre optic cable should be tested for quality and performance. This can be done by a power meter. A power meter measures the amount of light that travels through the fibre. Alternatively, the Optical Loss Test Set (OLTS) device measures the fibre optic cable’s attenuation or signal loss.

Is there a downside to repairing fibre optic cable?

The answer is that it depends. It can be as cost effective to install a new cable, but it depends on the type of cable and how easy it is to access the damaged section. Gaining access to the damaged cable is not always possible. If a cable is installed in a subduct for example, a hole may need to be dug in the ground to get access, which can lead to very high costs.

If you can locate the damaged area of the cable, it will still need splicing. Splicing requires precision and specialist equipment due to its complexity. Aligning the tiny glass fibres takes time and this can lead to longer downtimes and again, higher costs.

The world is increasingly relying on fibre optic cables to deliver data at high speeds, so it is important that they are properly maintained to ensure ongoing optimal performance. Identifying any issues as quickly as possible is vital to minimising disruption in the network.

Learn more about Prysmian Digital Solutions.