All Ground

All Ground® case

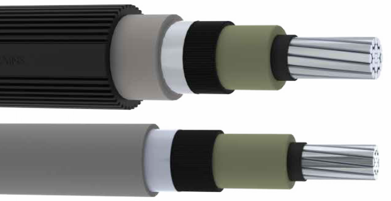

All-Ground® is an innovative solution to overcome the constraints of laying cables in low & medium voltage networks.

Project Developer will obtain savings through:

- Cost and transport on site of soft sand

- Clearing and tipping of the excavated soil

- No filling material control

- Reducing trench dimensions (depth and width)

Reducing Carbon Footprint

Cables can be buried directly, without additional sand bedding nor controlled filling material, which streamlines construction sites and helps to protect the environment, reducing the carbon footprint:

- Uses native soil

- No need to add soft sand or spoil

- Reduced site traffic

Sandy soil and Rocky ground

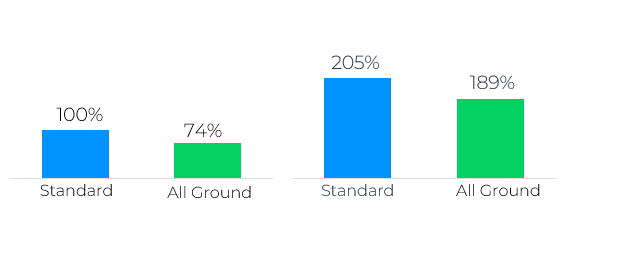

XZ1(S) 1x240 mm2 AL vs All Ground 1x240 AL > 0.6/1 kV to 1.8/3 kV Total costs - cable + installation - considering 50 MW plants | 25 km trench MW plants | 25 km trench

Specifically recommended in:

- Locations where sand is scarce or its transport to the job site is very expensive

- Locations with hostile climate where rain or wind can carry the sand away

- Locations where the terrain is not too rocky and allows re-use the trench material to cover directly without additional treated sand

Contact Us