Substandard cables cost lives

Substandard cables cost lives. It’s a fact we were reminded of recently at Prysmian when quality engineers at our Aberdare plant investigated the quality of annealing of the copper conductor of an unbranded flat twin and earth cable.

Annealing a solid copper conductor makes it softer and less brittle, which allows it to be twisted and bent during installation without breaking or cracking.

Elongation Test

An elongation test is used to assess the quality of the annealing by stretching the conductor until it fractures. The test demonstrated that the elongation of the unbranded cable was significantly less than the elongation of Prysmian’s 6242Y twin and earth cable.

Ineffective Annealing

We suspect that the reason for the conductor failing prematurely was that the cable was poorly manufactured. More specifically, the wire drawing process work-hardens the copper, so the conductor is heat treated, or annealed, to soften it and make it flexible again. In the case of the unbranded conductor, our quality engineers suspect the annealing process was ineffective, either because the annealing temperature or annealing time was incorrect.

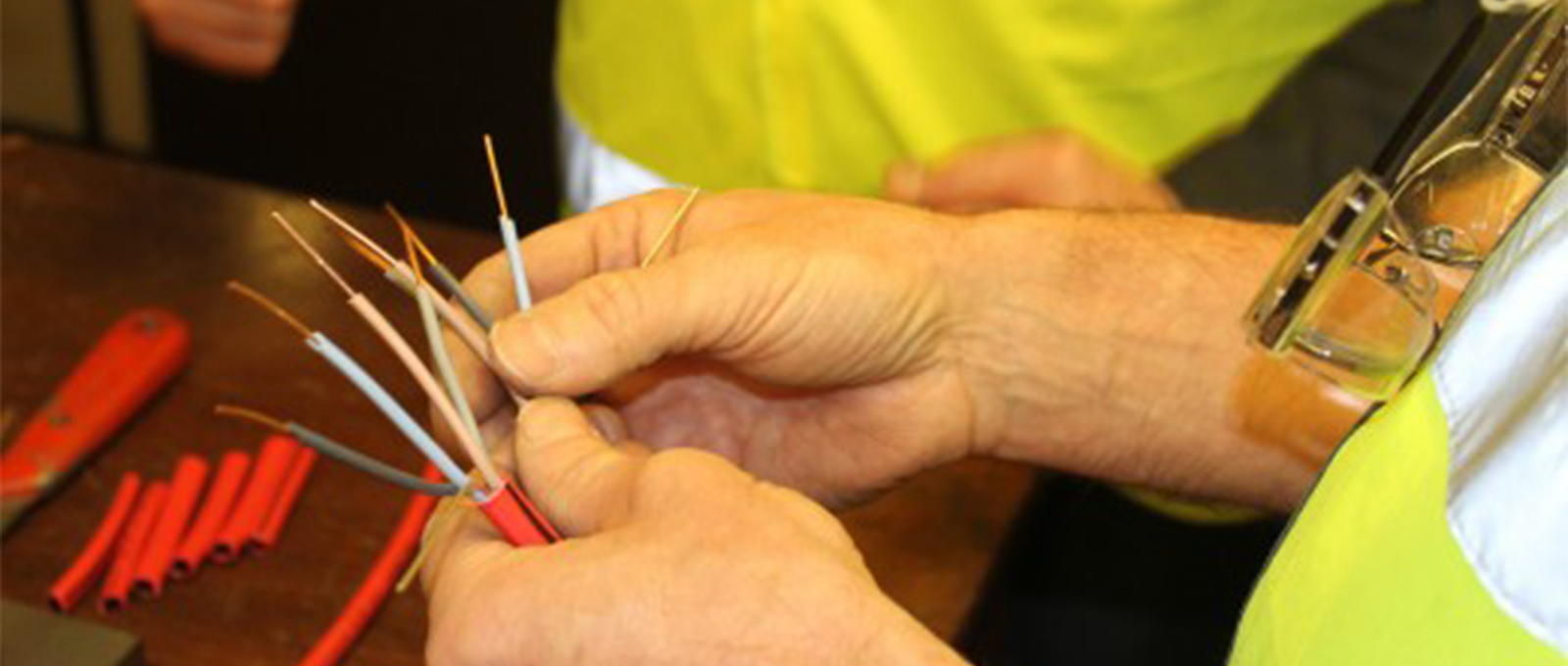

The unbranded conductor’s defective annealing means that it could easily be fractured during installation or be insecure in a termination, potentially causing arc faults. Similarly, the conductor could be fractured, or an existing fracture could be made worse, simply by checking the conductor is securely clamped in place by hooking a finger behind it and giving it a gentle tug.

The problem could be exacerbated if, during installation, the insulation cutting tool accidently nicks the copper conductor creating a weakness so the conductor could more easily fracture.

Common Cable Defects

Ineffective annealing is just one of the flaws that can be found in substandard cables. Whatever the fault, a major problem with sub-standard cable is that when installed it can be hidden for years. In fact, one of the most common defects in sub-standard cables is the copper conductor being deliberately undersized to save on material costs. This can cause the cable to overheat because there is not enough copper present for the cable to operate safely at its rated current.

Overheating conductors can cause a cable’s insulation and sheathing to crack and potentially fall off exposing the hot, live conductors – which could, potentially, start a fire. That is why substandard cables are dangerous.

CPR & BASEC

Prysmian manufacturers cable to the latest standards and regulations, including the new Construction Products Regulations. All its PVC sheathed wiring cables are approved by BASEC. That is why professionals choose Prysmian.

If you think that you’ve dealt with substandard cable on a job in the past or recently, please get in touch with the ACI and help us to create a safer future.